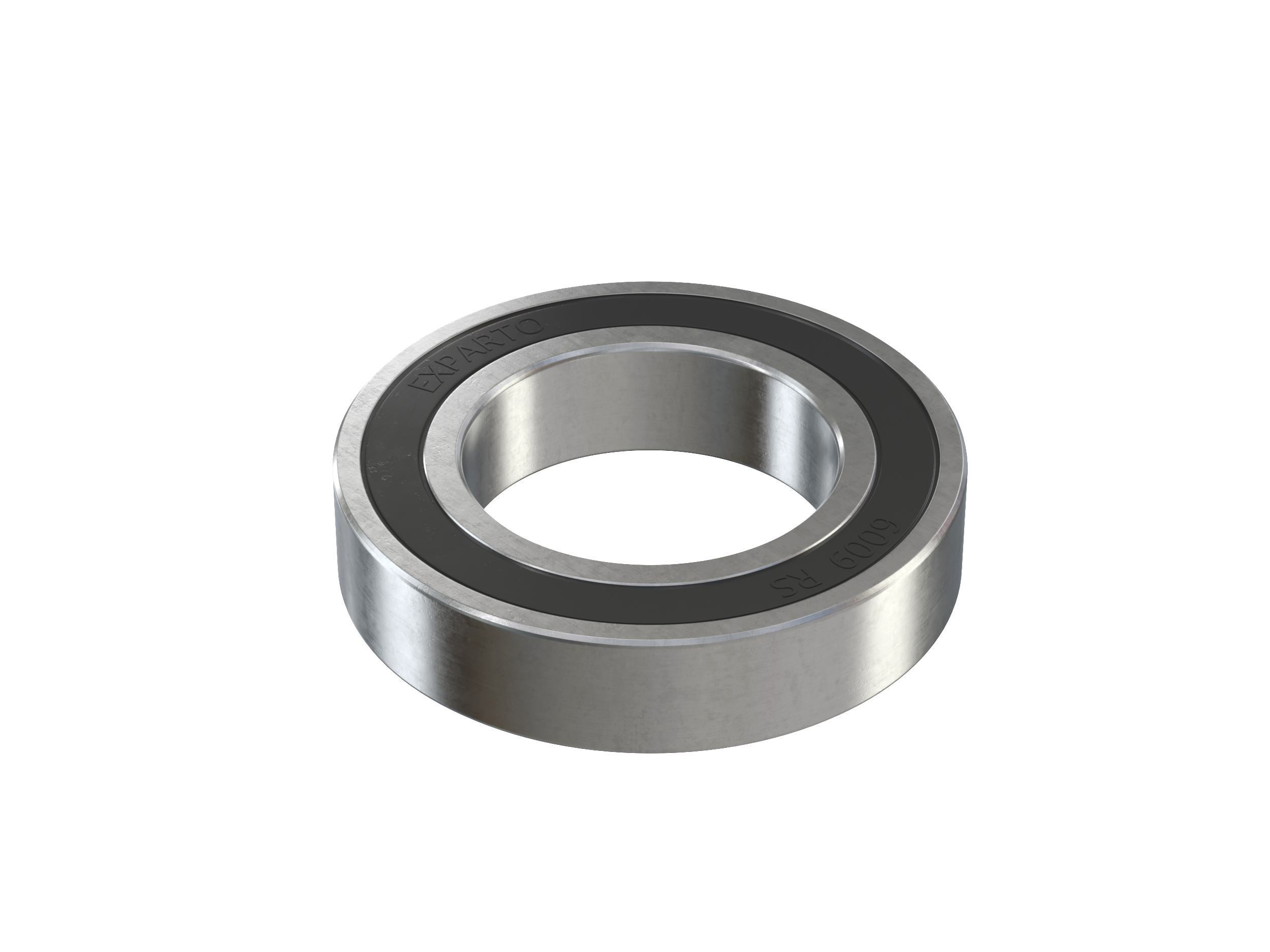

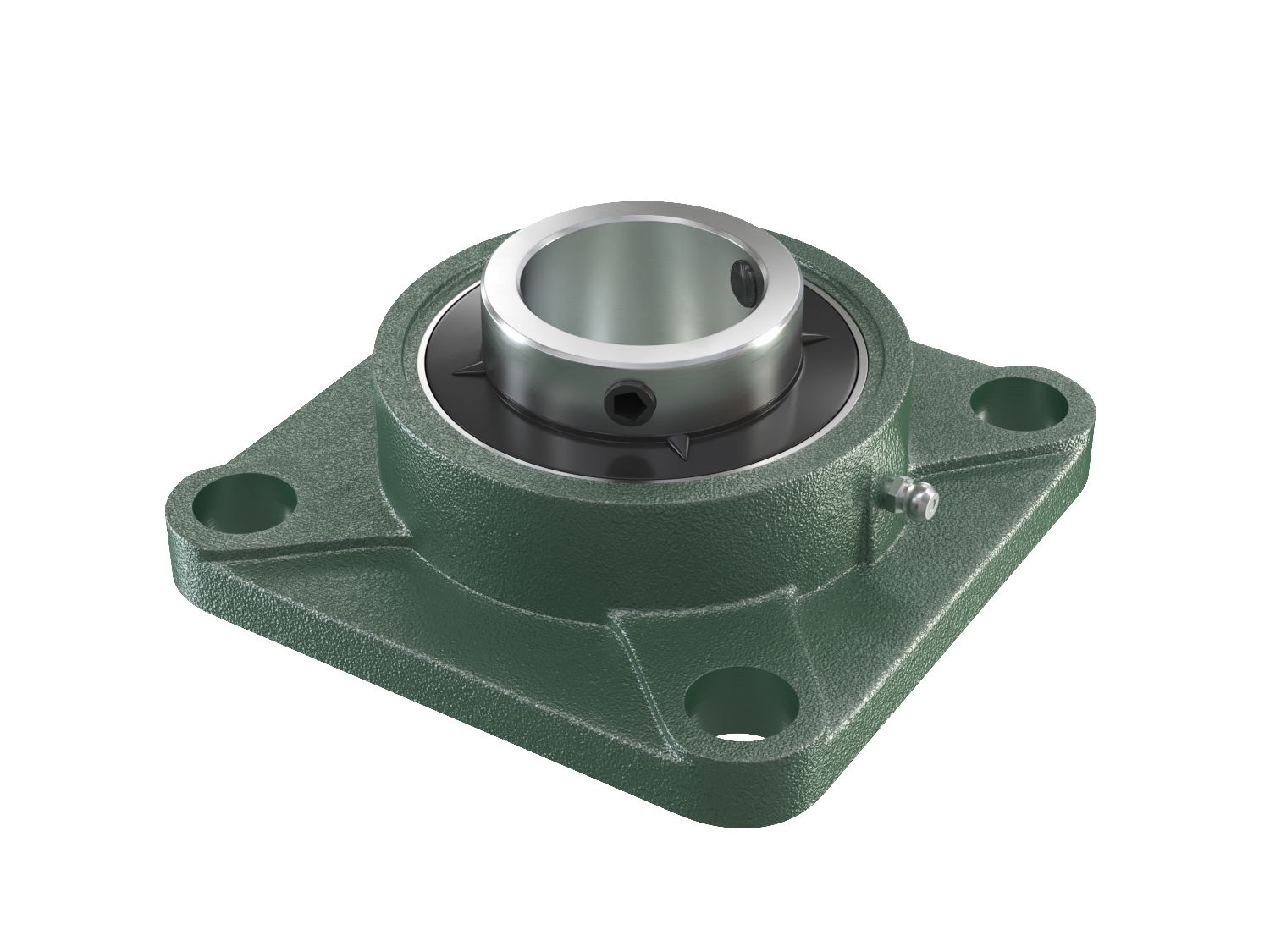

Bearings

Product description

Exparto bearings will provide installation in new as well as used machines. We have ball bearings, tapered roller bearings, cylindrical roller bearings, spherical roller bearings and needle bearings.

Equipment for: balers, baling presses, bale wrappers, disc mowers, rakes, swathers

During production we check:

- Geometrical dimensions. External, such as outer diameter of the balls, the shape of the raceway or the cage measured with a special, numerically controlled measuring machine, callipers and scanning microscopes; internal, such as the inner diameter of the ring measured with a CMM machine and control and measuring tools, i.e. two and three point sensor diameter gauges, internal micrometers with an accuracy of 0.001mm

- Hardness. Hardening of the entire workpiece after the machining process ensures a uniform, very high level of hardness. Control of the relevant values is ensured by using Vikers and Rockwell hardness gauges.

- Chemical composition. Even the best technological process cannot ensure 100% quality if the input material is incompatible. Exparto checks the chemical composition as soon as it enters the factory in order to ensure that all subsequent processes are correct.

- Microscopic and metallographic examination. Exparto, as one of few suppliers, performs metallographic inspection after the hardening process of working parts of bearings. This test allows us to examine parameters of heat treatment and to determine whether it was performed correctly.

We will manufacture almost any bearing in any class from P0 to P6, from any type of material with a lubricant selected by the customer.

Technical data on request.